Home

keyline2024-04-16T12:22:39+02:00FREE DELIVERY

Free Shipping on all orders over R2000

ONSITE TECHNICAL ASSISTANCE

Free onsite demonstrations & product testing

ONLINE SUPPORT

Access technical support online

ONLINE PURCHASES

Pricing for online purchases only

PROFESSIONAL MEASURING TOOLS

POSITION

For a Contractor, Engineer or DIYer, a projects’ starting point is to measure – ensuring that what is being built or installed, is POSITIONED correctly. STABILA is our positioning brand and has a wide range of measuring tools, laser distancers and professional spirit levels.

HEAVY DUTY POWER TOOLS & ACCESSORIES

OPEN

The next phase is to create an opening and this is generally done with a power tool. Under the product class OPEN, Upat represents Milwaukee, AEG and Eibenstock Power Tools. Together, these provide customers with expert drilling machines; rotary, combi and demolition hammers; hand-held coring machines, rigs, barrels and blades; and a vast range of drill bits; accessories; and world-leading heavy-duty power tools.

QUALITY ANCHORING SYSTEMS

FIX

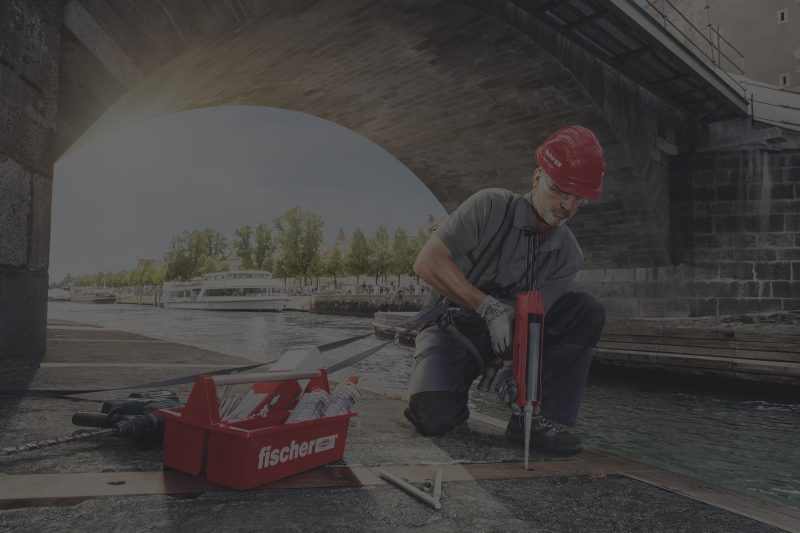

Next is FIXING, whereby things will need to be installed or fixed into place. As the exclusive South African agent for fischer we provide an extensive and technically superior range of fixings and installation systems including: nylon plugs, steel anchors, chemical anchors, screws, pipe clamps, special application fixings, gas and powder actuated nail guns.

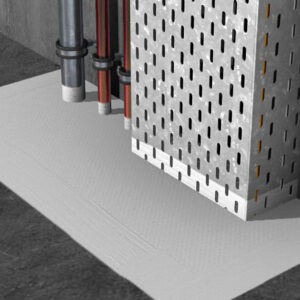

PU FOAMS, SEALENTS, FIRESTOP & VACUUMS

CLOSE

All projects need to be finished and this is where CLOSE comes in. The fixture or opening will need to be closed and sealed. Specialist Fire Protection systems, PU foams, sealants and adhesives, as well as industrial-strength vacuum cleaners form part of our CLOSE product offering.

-

Select optionsQuick ViewLevelling, Positioning & Measuring Tools, Electronic Spirit Levels, Featured Products, POFC, Position, Positioning, Spirit Levels

TECH 196 DIGITAL LEVEL

R5,313.00 – R7,339.300 out of 5Select optionsQuick View -

Select optionsQuick ViewFasteners, Featured Products, fischer, FIX - Quality Anchoring Systems, General Fixings, Nylon Wall Plugs

SX PLUS EXPANSION PLUG + SCREW

R6.530 out of 5Select optionsQuick View -

Select optionsQuick ViewFasteners, Featured Products, fischer, FIX - Quality Anchoring Systems, General Fixings, Nylon Wall Plugs

SX PLUS EXPANSION PLUG (LONG)

R2.68 – R5.850 out of 5Select optionsQuick View -

Select optionsQuick ViewFasteners, Featured Products, fischer, FIX - Quality Anchoring Systems, General Fixings, Nylon Wall Plugs

SX PLUS EXPANSION PLUG

R0.78 – R10.330 out of 5Select optionsQuick View -

BATTERIES & CHARGERS, Cordless Tools, Featured Products, Milwaukee, OPEN | Heavy Duty Power Tools & Accessories, Power Tools, Top 10

NRG M18 5Ah PACK

R6,893.100 out of 5 -

Read moreQuick ViewCordless Tools, Featured Products, Lighting, M18 HEAVY DUTY TOOLS, Milwaukee, OPEN | Heavy Duty Power Tools & Accessories, Power Tools

M18 UBL-0 LED UTILITY BUCKET LIGHT

R19,433.850 out of 5Read moreQuick View -

BATTERIES & CHARGERS, Cordless Tools, Featured Products, Milwaukee, OPEN | Heavy Duty Power Tools & Accessories, Power Tools, Top 10

M18 12Ah NRG PACK

R16,244.900 out of 5 -

Personal Lighting, Featured Products, Milwaukee, Power Tools

L4-HL2-301 – USB RECHARGEABLE HEADLAMP 600 LUMENS

R3,010.700 out of 5 -

Select optionsQuick ViewChemical Fixings, Featured Products, fischer, Fix, Fix, FIX - Quality Anchoring Systems, Injection Mortars, Plumbing, Steel Construction, Top 10

FIS VL 410 C VINYLESTER INJECTION MORTAR

R439.300 out of 5Select optionsQuick View

-

Read moreQuick ViewCordless Tools, Featured Products, Lighting, M18 HEAVY DUTY TOOLS, Milwaukee, OPEN | Heavy Duty Power Tools & Accessories, Power Tools

M18 UBL-0 LED UTILITY BUCKET LIGHT

R19,433.850 out of 5Read moreQuick View -

Personal Lighting, Featured Products, Milwaukee, Power Tools

L4-HL2-301 – USB RECHARGEABLE HEADLAMP 600 LUMENS

R3,010.700 out of 5 -

-

Select optionsQuick ViewLatest Products, Levelling, Positioning & Measuring Tools, Pocket Tapes, Position, Positioning, STABILA, Tape measures & Folding Rules, Top 10

BM300 POCKET TAPE MEASURE

R514.05 – R706.100 out of 5Select optionsQuick View -

Select optionsQuick ViewLevelling, Positioning & Measuring Tools, Pocket Tapes, Position, Tape measures & Folding Rules, Top 10

BM100 POCKET TAPE MEASURE

R186.30 – R346.150 out of 5Select optionsQuick View -

Select optionsQuick ViewSTABILA, Electronic Spirit Levels, Levelling, Positioning & Measuring Tools, Position, Positioning, Spirit Levels, Top 10, Type 196-2 IP65 spirit level

TYPE 196-2 IP65 SPIRIT LEVEL

R6,714.85 – R8,983.800 out of 5Select optionsQuick View -

Select optionsQuick ViewLevelling, Positioning & Measuring Tools, Position, Position, Positioning, Spirit Levels, STABILA, Steel Construction Solutions For POSTITION, Top 10, Type 80 Spirit Levels

TYPE 80 AS SPIRIT LEVEL

R714.15 – R1,177.600 out of 5Select optionsQuick View -

Levelling, Positioning & Measuring Tools, Lasers, Point & Line Lasers, Position, Top 10

LAX 600 MULTI LINE LASER (7pc)

R19,897.300 out of 5 -

Select optionsQuick ViewBuilding-Contractor, Electrical, Electrical Solutions For Position, HVAC, HVAC Solutions For POSITION, Levelling, Positioning & Measuring Tools, Plumbing, Plumbing Solutions for POSITION, Position, Position, STABILA, Standard Spirit Levels, Top 10, Type 96-2 Spirit Level

TYPE 96-2 SPIRIT LEVEL

R1,276.50 – R2,007.900 out of 5Select optionsQuick View

-

BATTERIES & CHARGERS, Cordless Tools, Featured Products, Milwaukee, OPEN | Heavy Duty Power Tools & Accessories, Power Tools, Top 10

NRG M18 5Ah PACK

R6,893.100 out of 5 -

Lighting, OPEN | Heavy Duty Power Tools & Accessories, Top 10

M18 HOSALC-0 Stand Light

R20,042.200 out of 5 -

BATTERIES & CHARGERS, Cordless Tools, Featured Products, Milwaukee, OPEN | Heavy Duty Power Tools & Accessories, Power Tools, Top 10

M18 12Ah NRG PACK

R16,244.900 out of 5

-

Select optionsQuick ViewCavity Fixings, Fasteners, fischer, FIX - Quality Anchoring Systems, Spring Toggle Fixings, Top 10

KDH SPRING TOGGLE

R23.28 – R25.450 out of 5Select optionsQuick View -

Select optionsQuick ViewFasteners, fischer, FIX - Quality Anchoring Systems, Frame/ Longshaft Fixings, Nail Plugs/ Hammerfix, Top 10

HAMMERFIX N-S CZK HEAD GVZ

R2.23 – R26.990 out of 5Select optionsQuick View -

Select optionsQuick ViewBoard Fixings, Building-Contractor, Cavity Fixings, Electrical, Fasteners, fischer, Fix, Fix, FIX - Quality Anchoring Systems, Top 10

GK PLASTERBOARD FIXING

R2.28 – R6.270 out of 5Select optionsQuick View -

Select optionsQuick ViewChemical Fixings, Featured Products, fischer, Fix, Fix, FIX - Quality Anchoring Systems, Injection Mortars, Plumbing, Steel Construction, Top 10

FIS VL 410 C VINYLESTER INJECTION MORTAR

R439.300 out of 5Select optionsQuick View -

Select optionsQuick ViewBolt Anchors, Fasteners, fischer, Fix, Fix, FIX - Quality Anchoring Systems, HVAC, Steel Construction, Steel Fixings, Top 10

EXA EXPRESS ANCHOR (A2 Stainless Steel)

R19.63 – R324.300 out of 5Select optionsQuick View -

Select optionsQuick ViewFasteners, fischer, FIX - Quality Anchoring Systems, General Fixings, Nylon Wall Plugs, Top 10

DUOPOWER PLUG LONG + SCREW

R9.51 – R23.920 out of 5Select optionsQuick View

-

Select optionsQuick ViewBuilding Contractor Solutions For CLOSE, Building Contractors, Building-Contractor, CLOSE - PU Foams, Sealants, Firestop & Vacuums, Construction Chemicals, Fix, Fix, Foam & Adhesives, HVAC, HVAC Solutions For CLOSE, Mechanical, Plumbing, Plumbing Solutions For CLOSE, PU Foams, Top 10

PU INSTALLATION FOAM

R207.00 – R258.750 out of 5Select optionsQuick View -

Select optionsQuick ViewCLOSE - PU Foams, Sealants, Firestop & Vacuums, Fire Protection, fischer, Mechanical, Mechanical Trade Solutions For CLOSE, Top 10

FiAM INTUMESCENT ACOUSTIC MASTIC

R112.13 – R200.100 out of 5Select optionsQuick View -

CLOSE - PU Foams, Sealants, Firestop & Vacuums, Fire Protection, fischer, Top 10

FFSC FIRESTOP COMPOUND

R1,646.800 out of 5 -

Select optionsQuick ViewBuilding Contractor Solutions For CLOSE, Building-Contractor, CLOSE - PU Foams, Sealants, Firestop & Vacuums, Fire Protection, HVAC, HVAC Solutions For CLOSE, Plumbing, Plumbing Solutions For CLOSE, Top 10

FCPS COATED PANEL SYSTEM

R1,085.60 – R1,100.550 out of 5Select optionsQuick View